In the ever-evolving landscape of metalworking and fabrication, bending machines are powerful allies, enabling the transformation of raw materials into the intricate components that fuel modern industries. These ingenious machines come in various forms, each tailored to specific bending requirements.

Bending machines and their general uses

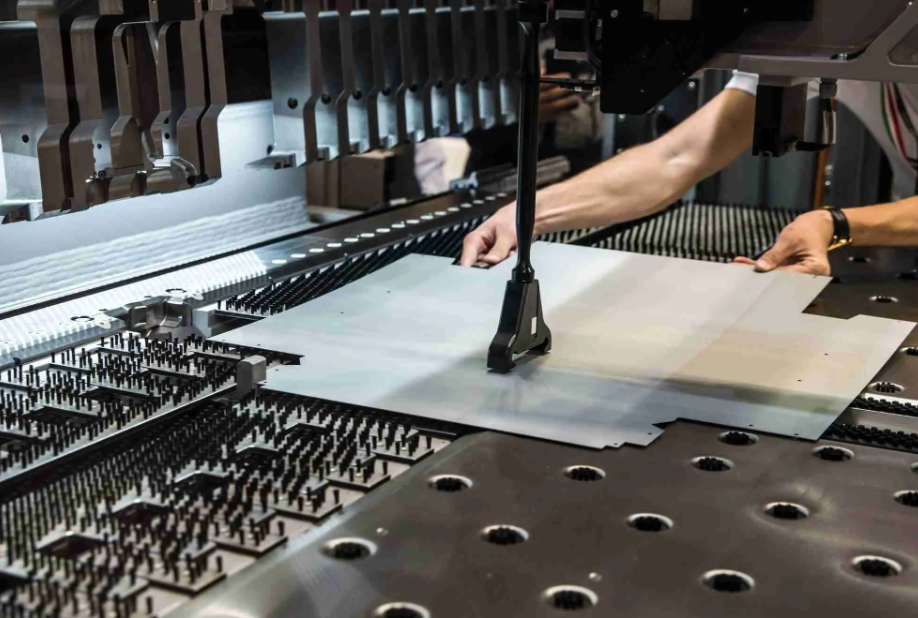

Bending machines, in their diverse forms, play a crucial role in shaping metal sheets and plates with exceptional precision and efficiency. Their applications span a wide array of industries, from aerospace and automotive to construction and consumer electronics.

The ability to bend metals accurately allows for the creation of structural components like beams, angles, channels, and pipes, forming the backbone of countless structures and machines. You can find out about the different types of bending machines here:.

Horizontal bending machines

However, as projects become more complex and specific bending requirements arise, traditional vertical press brakes may not always be the perfect solution. This is where horizontal bending machines step into the spotlight, offering a range of unique benefits that make them indispensable in certain applications. You can view a range of horizontal bending machines here: https://www.cotswold-machinery-sales.co.uk/euromac-bending-machines/horizontal-bending-machines.

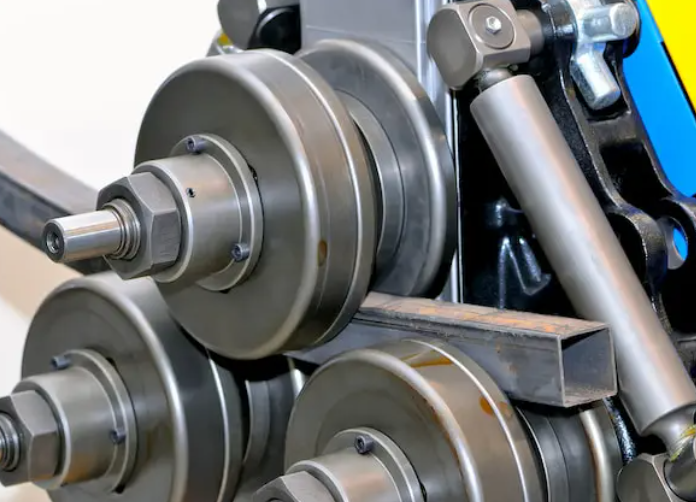

Horizontal bending machines are the go-to choice for projects involving heavy and thick metal plates that may pose challenges for traditional vertical press brakes. In industries such as shipbuilding, construction and heavy machinery manufacturing, these machines excel at bending large, wide plates with remarkable ease and precision. With their horizontal orientation, these machines provide unparalleled support and control over the entire length of long workpieces. Elongated metal sheets or profiles, which would prove cumbersome on vertical press brakes, find an ideal solution in the horizontal bending method.

Horizontal bending machines are renowned for their precision and ability to meet strict tolerances. Projects requiring intricate components and delicate bending angles benefit greatly from the accuracy these machines offer. For projects demanding symmetrical bending on both sides of a central axis, horizontal bending machines provide the efficiency and ease of use required to achieve perfect symmetry. And when continuous bending is needed for mass production, horizontal bending machines prove their worth by ensuring efficient and streamlined manufacturing processes.